Rotating equipment design and analysis is quite complex, with very stringent requirements on reliability, durability, and efficiency. The emerging focus on developing equipment and processes that are more sustainable, economical, and globally accessible has led rotating machinery designers and engineers back to the drawing board to answer questions like:

- How do we extract the last iota of efficiency from a pump or a turbine?

- How do we optimize the operation and maintenance of critical rotating equipment without increasing costs?

- How do we reduce time to market and stay ahead of the competition?

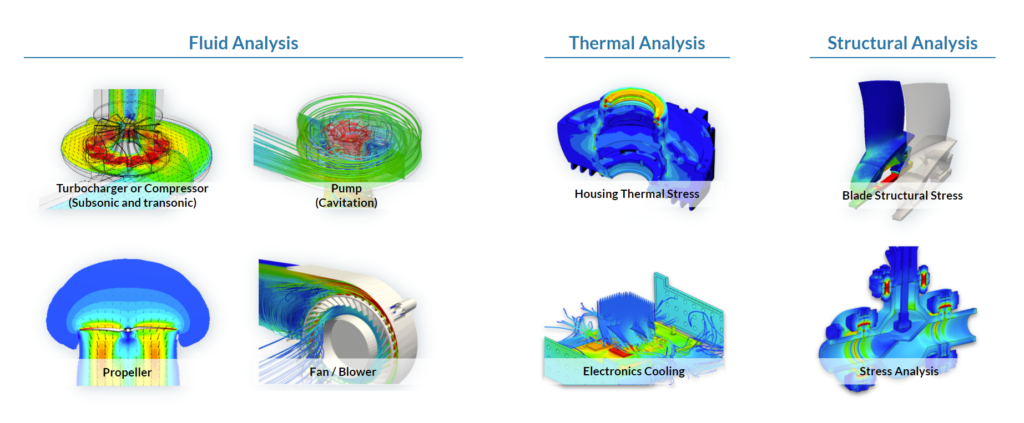

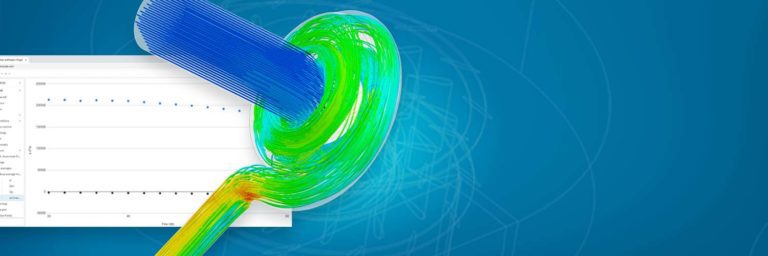

The answer is SimScale’s newest offering for rotating equipment simulations, which harnesses the power of the cloud to enable phenomenally fast and accurate simulations for flow and performance assessment of rotating equipment.

Fast and Accurate Simulation of Rotating Equipment

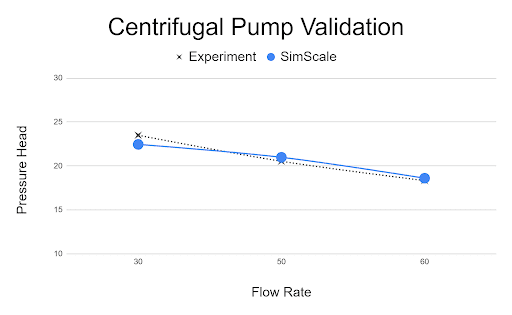

Consider the performance study of a centrifugal pump, which involves calculating the pump’s pressure head and efficiency for a range of outlet flow rates to generate what is known as the ‘pump curve’. Typically, a pump curve requires a minimum of six input data points and can take from days to months to produce in traditional software.

Our customer Benjamin van der Walt, from Hazleton Pumps, agrees. He says, “We averaged about 3-6 days to simulate 1 data point with AMI (transient simulation) and 9-15 hours with MRF (steady-state) on HPC. Generating a pump curve, with ideally 6 data points, can take up to a month”. With SimScale’s new proprietary rotating machinery technology, it is now possible to generate a pump curve for a medium-sized geometry within 15 minutes (See Figure 1).

The highly parallelized and cloud-optimized algorithms that form the backbone of our new technology enable users to make design decisions faster by running parametric studies at the same time as a single data point run.

Solution accuracy is critical to the design and analysis of rotating equipment and cannot be compromised at any cost. Cognizant of this fact, we have tested and validated our proprietary technology for a variety of academic and industrial use cases to obtain solution accuracy within 1-5% of experimental data.

Figure (2) depicts the pump curve parametric sweep, which includes a mesh independence study, and the results obtained from SimScale are within a 2% error of experiment. The solver is backed by high-fidelity numerical models and robust mesh generation techniques that can handle a variety of flow physics through different types of rotating equipment.

(Mesh size: 511,891 cells, runtime = 13-14 minutes, SimScale-Experiment error ~ 2%)

Accessible and Versatile Simulation

In rotating machinery simulations, it is common for traditional simulation tools to have turnaround times that run into days and also require a sizable investment in scalable hardware and data management processes. In most cases, the inherent complexity of rotating machinery simulation workflows can be quite frustrating for designers and engineers, resulting in a further increase in project lead times.

SimScale’s cloud-native simulation technology for rotating machinery not only reduces the simulation turnaround time to minutes but also drives the IT and hardware costs of companies to zero. We have invested heavily in automating and simplifying the simulation workflow so that rotating machinery designers and engineers do not get bogged down with the nuances of local software licensing and can instead devote their time to analyzing, iterating, and improving their designs.

Users can access the browser-based platform from anywhere in the world through a simple login, run multiple simulations simultaneously, and collaborate with team members on any projects they wish to share.

Cloud-Native Simulation for Rotating Equipment

SimScale is committed to making fast and accurate simulation accessible to all engineers working with rotating equipment and facilitating its adoption across applications and throughout the product’s lifecycle. We are confident that our proprietary technology for rotating machinery will help companies make significant savings in money and time, which they can channel back into doing what they do best – building better products faster.

Webinar: Pump Design Powered by the Cloud with Hazleton Pumps

Watch our on-demand webinar to see how simple it is to set up a simulation using our new technology for rotating machinery and get performance pump curves for all types of rotating equipment accurately and in minutes, not days: