From Formula 1 to NASA or civil engineering projects to wind turbine design, wind tunnel experiments are a key method of design evaluation in many industries. Using a purpose-built tunnel for wind provides a controlled environment in which engineers can test how airflow, lift, drag, and other forces affect a design—opening the door to optimization. When developing a product aerodynamically, a racing car, for instance, wind tunnel testing is the next best thing to real-life testing. Accurate aerodynamic assessment could therefore mean the difference between winning and losing out to competitors and competing products.

Wind Tunnel Experiments A Labor-Intensive Process

Wind tunnels can be seen as huge tubes with air blowing through them, usually created by tunnel drive fans. They replicate the impact of air on the object, person, or vehicle inside the tunnel, whether along the ground or in the air. Wind tunnels have been used to measure aerodynamic forces on wind tunnel models for over a century, since the early days of aeronautic development.

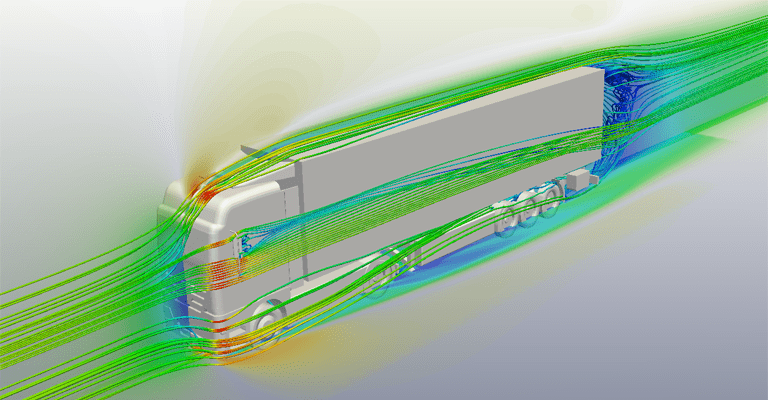

Air is transparent and therefore difficult to visualize. For wind tunnels, flow visualization methods are separated into two categories; qualitative and quantitative. For qualitative assessment, there are a number of different tactics that can be applied to better visualize airflow. Smoke or fog can reveal airflow patterns, oil or paint applied to the model can show the transition from laminar to turbulent flow, and tufts can help identify the direction of flow.

To gather data, quantitative assessment of particle movement is required and demands more resource-intensive testing. Where smoke or dust is used, particle image velocimetry (PIV) using lasers and cameras capture particle movement. Pressure taps on the model surface can be attached to a pressure transducer to measure pressure accurately. More over, flexible yield in airflow can be calculated by taking images of the movement of specific markers placed on the wind tunnel model, known as model deformation measurement (MDM). These are just a few of the labor-intensive methods used in traditional wind tunnel experiments.

Download our ‘Tips for Architecture, Engineering & Construction (AEC)’ white paper to learn how to optimize your designs!

Wind Tunnel Model Overview

When dealing with large vehicles or structures, scaled-down models are used and placed into a wind tunnel to assess the design for aerodynamic efficiency. Commonly, wind models are made of materials such as steel, plastic, or composites which are being increasingly used increasingly since the global uptake of 3D printing methods. They can range in size, depending on the tunnel, from miniature town planning models to entire aircrafts such as those tested in the world’s largest wind tunnel facility, NASA’s National Full-Scale Aerodynamics Complex (NFAC). Producing these models demands time and resources and can limit the number of designs that can be tested due to budget or deadline constraints.

“In simple terms, wind tunnels are like huge hair dryers—giant tubes of air where you can control airflow and air temperature. There is a huge amount of ingenuity required to obtain data from wind tunnel experiments; smoke, paint, lasers etc. And also a huge amount of work! With CFD, it’s all just a click away.”

— Edoardo Frigerio, SimScale Engineer and Aerodynamics Enthusiast

Modern Wind Tunnel Experiments Digitally Transforming Wind Tunnels & Models

In the past decade or so, the approach to aerodynamics has dramatically transformed as industries begin to adopt and embrace new technologies. Typical wind tunnel testing as a physical practice has been upgraded with new digital tools that offer support to engineers in many areas. Computational fluid dynamics (CFD) is now a standard practice for most companies whether they rely solely on CFD results or move on to gathering experimental data from physical tests afterward. Both methods can also be used to validate each other in order to improve the reliability of results.

Digital wind tunnel models generated with CAD/CAE programs can be produced, meshed and uploaded into a CFD program to be aerodynamically tested with simulation. The ability to digitally create and test prototypes drastically cuts down on costs and time resources, allowing engineers to quickly make design iterations and, in cloud-based platforms like SimScale, even test varying design renditions in parallel.

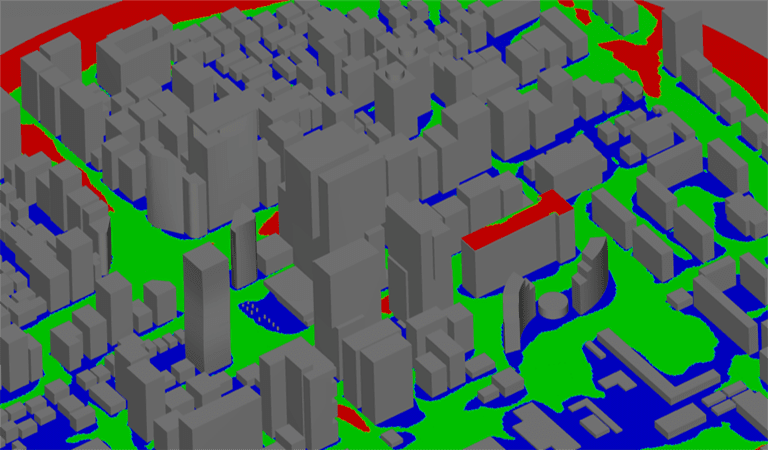

Project Example with New Feature Pedestrian Wind Comfort Analysis

When it comes to wind tunnels, many will think immediately of automotive or aerospace projects, however wind tunnel testing is of extreme importance in the AEC industry. Taking the Gangnam District in South Korea as an example, this project demonstrates how digital wind tunnel testing can be used to assess wind patterns and air behavior in an entire urban area (whether a proposed plan or already in existence). Using CFD, you can quickly and easily test an area for wind comfort with a number of different wind speeds entering from whichever direction. In doing so, factors such as terrain, local wind data, and wind engineering standards are also easily taken into account.

See more on the project, and SimScale’s Multi-Direction Pedestrian Wind Comfort Analysis tool, in this webinar recording on YouTube.

Modern Wind Tunnel Experimentation A Tale of Two Approaches

While 30 or 40 years ago, physical wind tunnel experiments were pioneering aerodynamic analysis, the shift towards the digital era has demanded that practices become faster and less cost-intensive. Technology has already advanced so rapidly that simulation has been widely adopted in many industries as a useful aid in product research, development, and design. However, it is the combination of both virtual and experiment data that provides engineers and designers all over the world with the confidence that their design will perform in the best and most efficient way possible.

Other Wind Resources from SimScale:

- Blog Post: Virtual Wind Tunnel Online

- Success Story: Aerodynamic Simulation for Formula Student Car

- Project Spotlight: Wind Experiment

- Blog Post: A Guide to Wind Analysis