In 2018, the UK government implemented new BB 101 guidelines which aim to improve indoor air quality, thermal comfort, and ventilation in schools across the country. In its wake, the marketplace for school ventilation systems has grown, as educational facilities and firms alike now, more than ever, need to evaluate the performance of their ventilation designs before installation to comply with the new standards. SAV Systems—a UK based firm and leader in low carbon technologies and energy-efficient heating system—teamed up with SimScale to evaluate the airflow and temperature distribution in a classroom through mechanical ventilation simulation using convective heat transfer.

The Customer SAV Systems

Operating in the UK for over 20 years, SAV Systems is a supplier as well as the market leader in heat networks. SAV has a number of product lines including Danfoss heat interface units, EC Power Micro-CHPs, Kamstrup Energy meters, and most importantly AirMaster MVHRs also known as SVUs (smart ventilation unit), which is the subject we will discuss in this article.

SAV Systems partners with Danish technology firms and experts to draw on their decades of experience to create better systems and ultimately smarter solutions in the relatively new UK mechanical ventilation market. This often puts them ahead of the curve among national competitors, as they aim to raise standards towards a brighter and more sustainable future.

In our collaboration, SimScale worked with SAV Systems to explain how to evaluate the airflow and temperature distribution in a classroom by running a convective heat transfer simulation.

The aim of this project was to optimize their ventilation system design for best results, and to combat poor ventilation in UK classrooms.

The Problem Poor Ventilation in UK Schools

The quality of insulation and the requirements of building regulations have massively improved, but conversely, this has made buildings less breathable so that they require additive mechanical ventilation systems to maintain healthy air quality. If air quality is too poor and carbon dioxide builds up it can make occupants uncomfortable, but even more, it decreases the ability of the occupants within the room to concentrate. For a learning environment, this is especially bad. So in 2018, regulatory bodies in the UK stepped in to combat inadequate ventilation in classrooms through the implementation of BB 101.

UK Standards BB 101

The BB 101, or Building Bulletin, provides guidance and standardizations on ventilation, thermal comfort and indoor air quality in schools. This document describes the factors that affect the indoor environment of schools, setting out the regulatory framework for ventilation in classrooms and gives recommended performance levels for compliance with UK regulations. One large improvement of the BB 101 was the incorporation of standardized CO2 levels, whereas previous guidelines focused merely on flow rates.

For example, the daily average CO2 levels of a classroom should fall anywhere between 350 and 1,000 ppm (parts per million). If the CO2 concentration of an indoor space surpasses this, occupants will experience drowsiness and poor air quality. Anything over 2,000 ppm can even result in complaints of headaches, loss of attention, increased heart rate, and even nausea. Efficient ventilation aims to mitigate these problems, as it works to produce good indoor air quality, which in turn improves concentration, alertness, and sense of wellbeing.

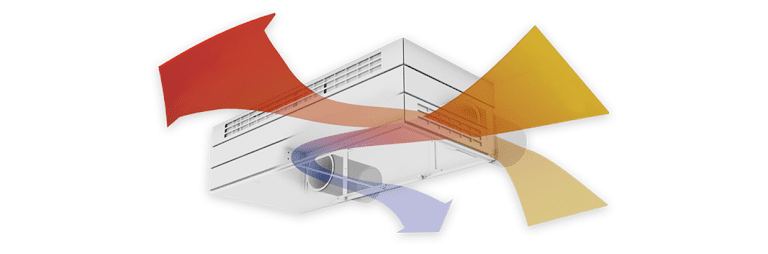

“While SAV Systems has a wide range of AirMaster SVUs (decentralized MVHR units), our simulation focused on the AM 800, which is typically used for classroom ventilation. These devices aim to provide a consistent level of good indoor air quality without the risk of draught while maintaining air filtration standards and effective noise control. The systems make use of the Coanda effect, or the ability of a stream of fluid emerging from an orifice to follow an adjacent flat or curved surface, and to entrain fluid from the surroundings so that a region of lower pressure develops, while also extracting stale air and CO2.

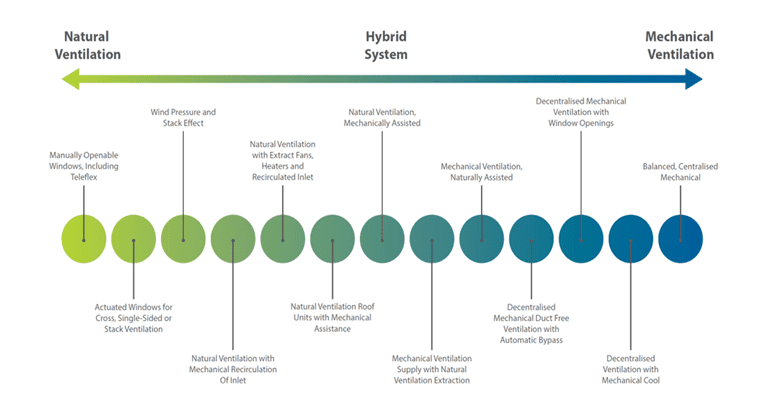

Mechanical Ventilation Simulation Natural Ventilation vs. Mechanical Ventilation Across Europe

This spectrum from natural ventilation to mechanical ventilation shows all the methods available, but in most European countries natural ventilation is no longer an acceptable practice when used as the sole ventilation system. This is because it fails to filter outdoor air being brought into an indoor space, as well as fails to consider and adapt external environmental changes that may occur creating inconsistent airflow. Unfortunately, in the UK, it is still considered a common practice, although new regulations are working to improve this.

Employing Mechanical Ventilation Simulation Classroom Thermal Comfort

The temperature in a room is controlled by the extraction unit paired with a radiator to ensure good thermal comfort. In turn, thermal comfort is evaluated by ASHRAE standards (PMV, PPD, etc.) taking into account the temperature and velocity of the flow. A traditional solution to this was simply opening a window to let in the fresh air.

Though this method works to solve the issue of CO2 buildup, it again fails to filter out pollutants from the outdoor environment. It also creates a draught. Cold draught can be an issue in classrooms where the ventilation system has not been designed to modern standards. The greater the indoor-outdoor temperature difference, the greater the draught. The Coanda effect, facilitated by mechanical ventilation, enhances air mixing and provides a better temperature distribution.

Evaluating Classroom Comfort

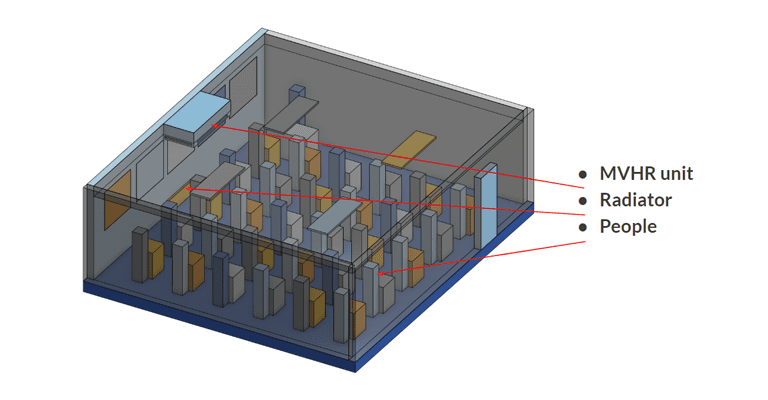

The goal of SimScale’s collaboration with SAV Systems was to test their AirMaster (decentralized MVHR unit) design which they are primarily supplying to schools, learn how to model and simulate this device for a draught-free classroom, and ultimately evaluate the temperature distribution within that room through mechanical ventilation simulation.

In order to do this, convective heat transfer was used, to assess a classroom environment where temperature changes in the fluid lead to density variations and movement of the fluid due to gravity. This solver can be used for natural convection but also for forced convection when air movement is induced by external forces, such as wind, pumps or fans.

Simulation Setup The Mechanical Ventilation Simulation

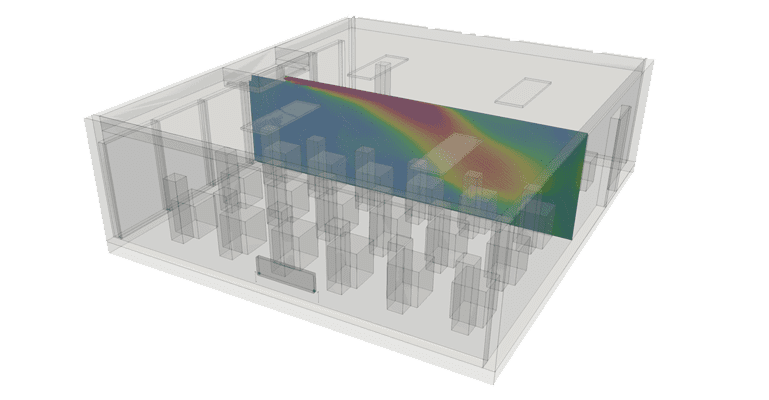

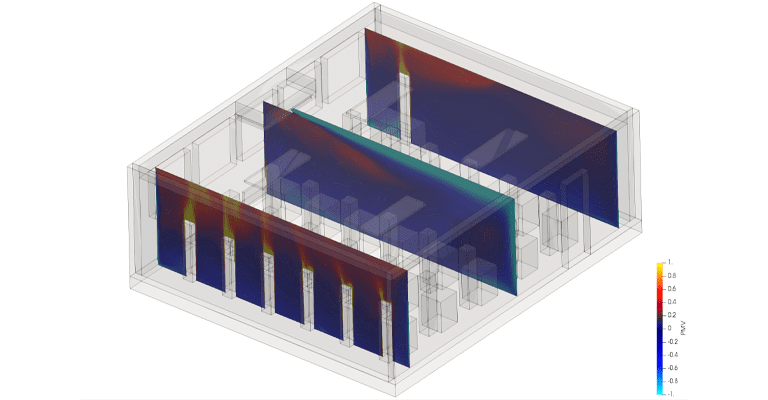

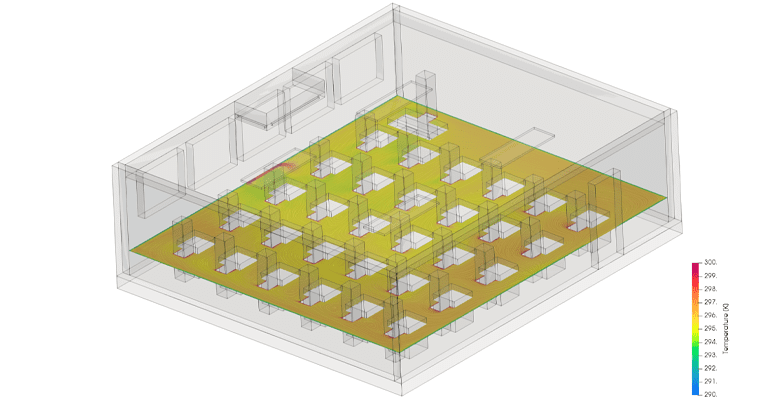

A simplified classroom CAD model was created with some interesting elements for the simulation, as shown below. The analysis type used was a convective heat transfer in a steady state, employing a k-omega SST turbulence model and incompressible flow. The 8.8 million-cell mesh was automatically generated and refined, and radiator, inlet/outlet, as well as inflation layers were defined.

The Results Improved Ventilation Design

Through the simulation project, it was found that the AirMaster allows a temperature range from 290K to 300K (17C – 27C), where cooler regions exist around the walls and floor, and airstream and warmer regions at the radiator and above occupants. The predicted mean vote (PMV)—a calculation including a particular combination of air temperature, mean radiant temperature, relative humidity, airspeed, metabolic rate, and clothing insulation—was found to be within the desired range around the room (between -0.5 and 0.5). Additionally, through design iterations, the mechanical ventilation system was found to work at optimal conditions when closer to the opposite wall.

The reference height given by ASHRAE for thermal comfort with seated people from was evaluated, and a uniform distribution all over the room around 22°C was found. Using this same height and testing PMV once again led us to confirm the previous results found by the vertical slices; great thermal comfort and distribution rate along the room were achieved.

Using SimScale, SAV Systems was able to carry out a complete HVAC CFD evaluation. The AirMaster unit performed as expected, with no undesired draughts , uniform temperature distribution, and great thermal comfort.

To watch our full collaborative webinar with SAV Systems, find the video here and follow along.

Conclusion & More Ventilation Resources

As regulations in the UK increase around improving ventilation system design for classrooms and indoor spaces alike, one can predict that online mechanical ventilation simulation through platforms like SimScale will be used more and more to quickly and efficiently optimize ventilation designs. Companies like SAV Systems are doing their part to not only supply these optimized systems to schools around the UK, but are striving to make changes to improve the learning environments, and overall health, of children in the UK.

Jonathon Hunter Hill, Sector Manager for Education from SAV Systems says, “I feel, as an engineer, you don’t just have an engineering obligation, but also a moral obligation to make sure children have good indoor air quality. It’s not their choice to go to school, but it is our choice what quality of school environment we give them.”

For more on ventilation from SimScale, check out our resources below:

- Stack Effect & Ventilation System Design

- Industrial Ventilation: Testing Exhaust Fume Extraction System Designs

- Validating Passive Ventilation in Building Design with Fluid Flow Simulation

- Garage Ventilation System Design: CO Removal with Jet Fan Placement

- Natural Ventilation Validation with CFD Software in the Cloud

- How to Improve Negative Pressure Room Ventilation with CFD Simulation

- Where to Place Ventilation for Maximum Comfort in a Building

- How to Optimize Displacement Ventilation Design with CFD