CFD is the acronym for ‘computational fluid dynamics’, which, as the name suggests, is the branch of fluid mechanics that uses computers to analyze the behavior of fluids and physical systems. CFD modeling and analysis became a popular online simulation solution as the difficulty grew in applying the laws of physics directly to real-life scenarios to make analytical predictions. This fact became especially prevalent for fluid flow and heat transfer engineering problems.

In this article, we discuss the basic questions you have on CFD modeling.

What are Fluid Mechanics and Heat Transfer?

Fluid mechanics is the science that studies the physical behavior of fluids: liquids, gases, and plasmas. As such, it relates the forces acting on a fluid body and the consequent changes in internal fields such as velocities, pressure, density, and temperature. These relations are mathematically stated through differential equations, the Navier-Stokes equations being the corollary of the known laws for the behavior of viscous fluids. Here are the Navier-Stokes equations in simplified vector form:

On the other hand, heat transfer is the study of how thermal energy gets generated, stored, transported, and transformed. The main mechanisms it analyzes are:

- Thermal Conduction (Diffusion): The spread of heat across materials, such as solids or fluids, from regions of high temperature to regions of lower temperatures.

- Thermal Convection: The transport of heat with the flow of a fluid. Fluid flow can be driven by external work (forced convection) or by buoyancy, which is the movement of fluid with varying density in the presence of gravity (natural convection).

- Thermal Radiation: The generation and absorption of heat through electromagnetic waves.

- Phase Changes: The release or absorption of heat through transitions such as boiling, melting, condensation, etc.

Laws of physics for fluid flow and heat transfer are expressed in terms of differential equations, most of the time with many related variables. It happens to be that some of the equations for both fields are similar; for example, the diffusion of a scalar through a flow field and the diffusion of temperature.

The most general of these laws for the flow of fluids is the set of Navier-Stokes equations. Yet, due to their complexity, solving these equations for exact solutions can only be achieved in the simplest of cases.

For more information on fluid mechanics and heat transfer, click the buttons below.

How Does Computational Fluid Dynamics Work?

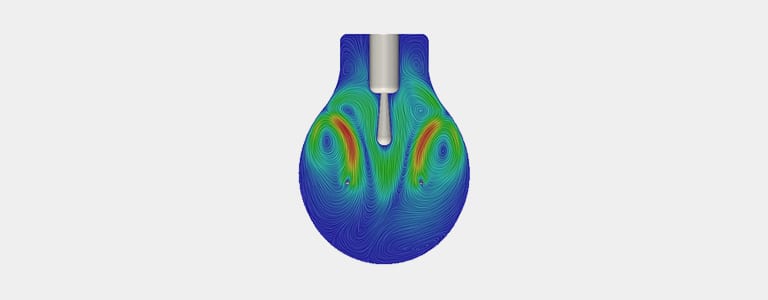

This is where numerical analysis and computers come into play; online simulation. By using numerical approximations, CFD turns the full differential equations into systems of linear equations, which are then solved to obtain field values such as velocities, pressures, and temperatures on a finite (but often large) number of points in the domain of the problem.

Although numerical methods for obtaining approximate solutions to differential equations have existed for many centuries, the ability of computers to store large amounts of numerical data and perform fast operations on them is what has turned technology into the most practical tool for physicists and engineers. At the same time, this means that one often finds that the application of CFD to practical problems is limited by the computational power available.

CFD analysis allows for the modeling of fluid because of its versatility in numerically solving equations of state and physical behavior expressed in differential or explicit form. Furthermore, CFD modeling analyses as heat transfer problems are of paramount practical relevance, any competent simulation tool includes modules to calculate temperature distributions alongside pressure and velocities. Some applications can also include analysis of solids for elastic deformation or chemical reactions, among other non-fluid applications.

Typical Use Cases of CFD Modeling and CFD Online Simulation

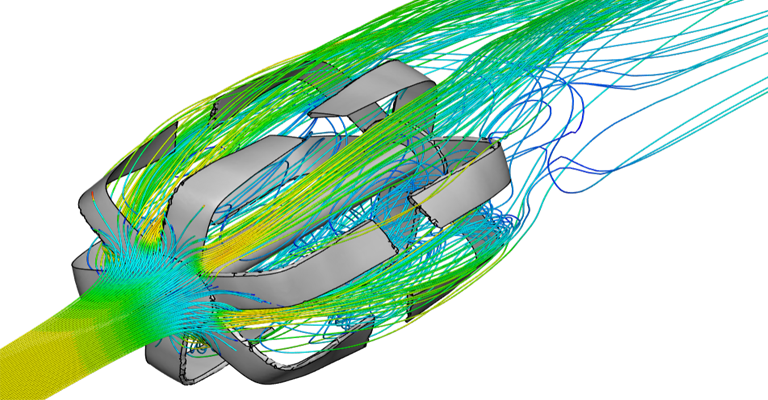

- Flow through piping and accessories such as valves, tees, and reductions, in order to predict pressure drops, velocities, and vortex formations.

- Vehicle aerodynamics, including automotive and aircraft, in order to predict drag, lift, and downforce.

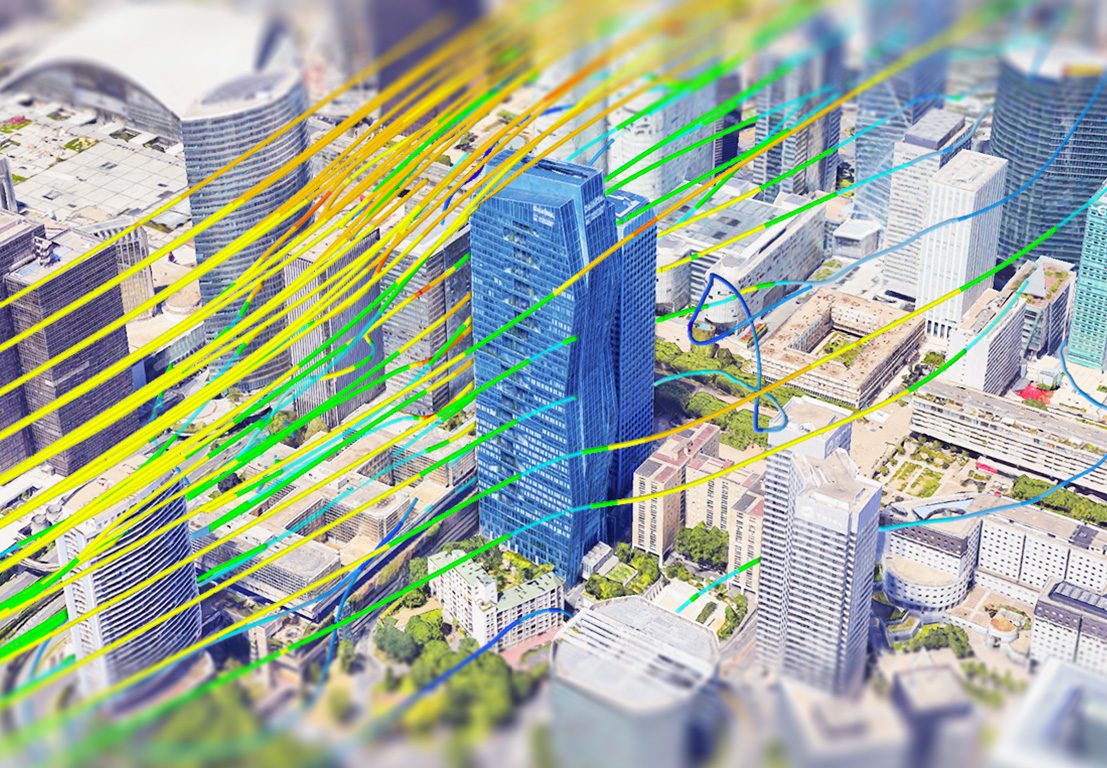

- Wind engineering for buildings and wind analysis, to predict wind forces, vortex formation, and pedestrian comfort.

- HVAC systems, to assess the performance of ducts or optimize thermal comfort for artificial or natural ventilation and for energy consumption.

- Heat exchangers, to predict heat transfer and pressure drops.

- Electronics cooling, to predict natural and forced cooling strategies performance.

- Windmills, to predict blade lift, velocity, and power generation at given wind speeds.

- Pollution dispersion and airborne contamination control, cleanroom design.

- Ship and offshore structures for hydrodynamic performance.

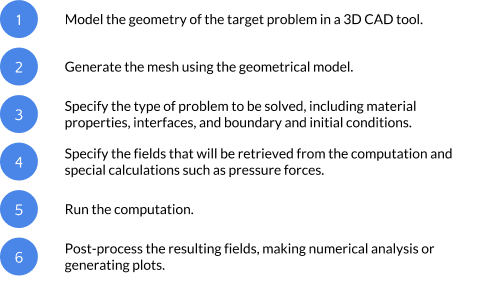

Typical Characteristics of a CFD Problem

- The problem is defined over a closed geometry, referred to as the ‘domain’ enclosed by its ‘boundary’.

- The phenomena to be simulated are well defined, such as the presence of heat transfer, turbulent flow, chemical reactions, multiple phases, multiple bodies, etc., with known material properties and coefficients for state equations.

- Initial values, as well as values on the boundaries for the considered fields, are known. This might include pressures, flow velocities, walls, temperatures, heat sources, etc.

- The geometry of the domain is split into small basic shapes known as ‘cells’. The set of all cells is known as the ‘mesh’. The size of cells will determine the precision of the solution (the smaller, the better), but the number used will define the demand for computer memory (the smaller cells, the higher the count, the more memory will be consumed, and the longer time the solution process will take).

For more information on CFD simulation and the underlying principles, check out our guide to CFD by clicking the button below.

What Commercial CFD Software Is Available?

There are many CFD software offerings in the market, some of them of general-purpose with many capabilities and some tailored for specific applications. Companies even develop their own in-house codes for specific engineering tasks. Here is a list of the most used general-purpose suites in the industry:

- ANSYS Fluent and CFX

- STAR-CCM

- COMSOL

- OpenFOAM (Free, Open-Source)

- CAD-integrated tools in SolidWorks/Autodesk (basic functionalities)

A very good alternative to traditional, desktop workstation-based suites is the online simulation platform SimScale. It is built upon established solvers, including OpenFOAM, providing an easy workflow and a modern user interface accessible through any web browser with computations run on remote cloud servers, which helps relieve your local machines from intensive and lengthy tasks.

Explore CFD in SimScale

What are Key Industries That Use CFD Analysis?

Here are some of the most representative industrial sectors leveraging the power of CFD analysis and a short description of why they do it:

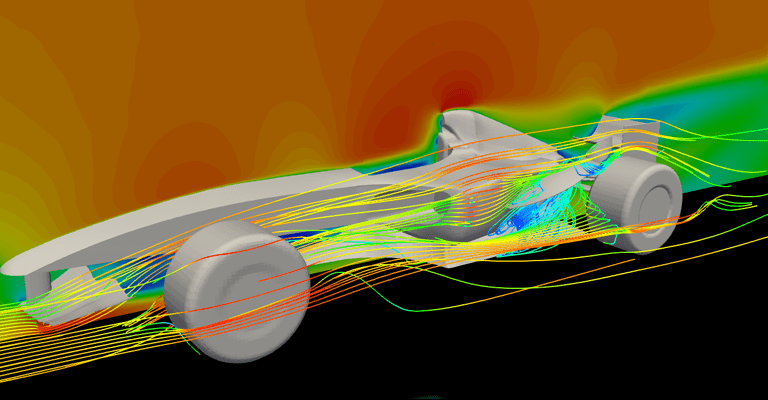

Automotive

The automotive industry makes use of CFD for many applications, with the most important being vehicle aerodynamics. CFD analysis is used to predict drag, downforce, and stability against cornering/crosswind flow. Other automotive applications include engine combustion and thermal performance, ventilation, exhaust fumes, and more. Here is a link to an example project simulating the aerodynamics of an F1 car.

For more information on the automotive industry, click the link below.

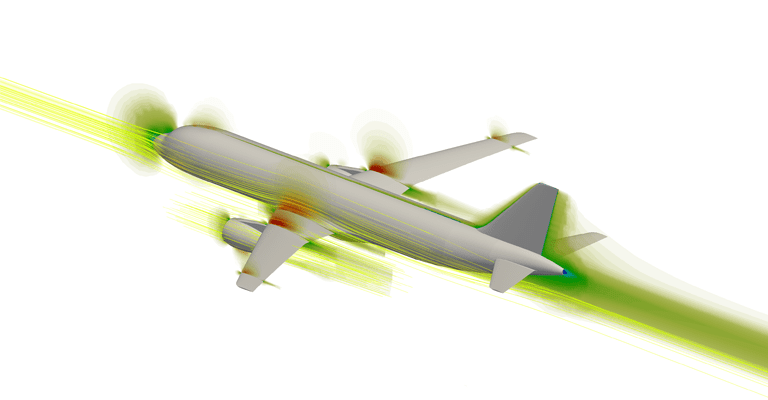

Aviation

In the aviation industry, the main application of CFD is also aerodynamics, with the aim of optimizing the lift/drag ratio and studying instabilities. Here is an example project on airplane aerodynamics that touches on how simulation can give valuable insights into airflow and aircraft performance. Other important fields for online simulation within the aviation industry include ventilation and air filtration.

For more information on aviation and aerospace, click the link below.

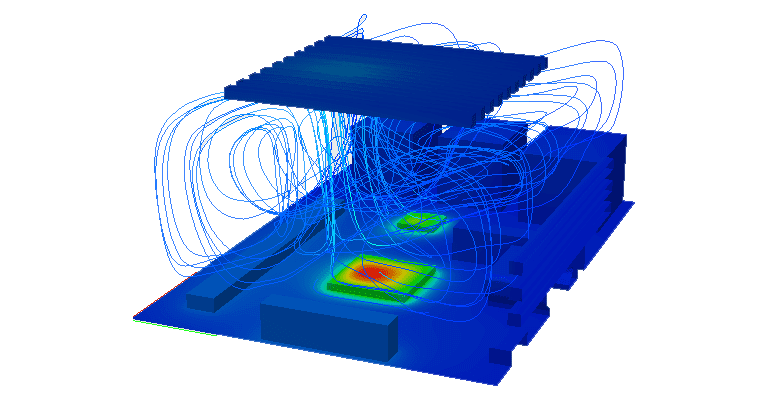

Manufacturing

In the manufacturing industry, CFD is used to study the performance of the cooling system in consumer products, especially those making use of electronics. Here is an example project—enclosure design for a Raspberry Pi.

For more information on the manufacturing industry, click the link below.

Why is CFD important?

As product development cycles are getting shorter in time, and as more and more products rely on precise performance to achieve success, numerical online simulation is always gaining more relevance. Its ability to make precise performance predictions with fast, reliable, and easy workflows unleashes the possibility of carrying optimization right from the engineer’s workstation, even before the first prototypes are built.

CFD simulation is not the exception to this trend, and with online simulation offerings such as SimScale, which brings lots of computational power and optimal workflow at affordable prices, without the hassle of complex CFD software and hardware installations, these advantages are reachable to a larger number of companies, even those on tight budgets.

How to Learn CFD Analysis with SimScale

If you wish to learn more about CFD modeling, CFD online simulation, and CFD and start leveraging its advantages for your projects, I recommend you to:

- Sign up for a free SimScale account, where you can start simulating right away. Check, for example, the repository of public CFD projects for airflow simulation and more.

- While you’re at it, check out the SimScale blog for all things CFD.

- Read the SimWiki page on everything related to Computational Fluid Dynamics (CFD) or explore other relevant pages in SimWiki.