The indoor environment of any building determines the health, productivity, and comfort of its occupants. The systems used to maintain that environment also significantly affect the overall energy consumption of the building, making an efficient, well-designed HVAC system one of the most important aspects of building design.

There are two main thermal comfort standards that specify how to evaluate indoor environment for occupants of commercial and residential buildings: ASHRAE 55 and EN 15251. These standards provide HVAC system designers with a clear set of measurements and requirements that their designs need to meet in order to ensure a sufficient level of indoor thermal comfort, helping them determine the optimal design configuration. This is where computational fluid dynamics (CFD) is extremely useful, as it enables designers to virtually test various design versions at all stages of development for a relatively low cost, allowing for a better design workflow.

Sign up & check out our SimScale blog for much more!

For a live demonstration of how CFD can be used to ensure the compliance with EN 15251 and other thermal comfort standards, watch the recording of this webinar:

The EPBD and EN 15251

The Energy Performance of Buildings Directive (EPBD) was adopted in 2002 with the intention to improve the energy efficiency of buildings. It was inspired by the Kyoto Protocol which commits the EU countries to reduce carbon emissions and mitigate the impact of climate change.

As part of the EPBD implementation, the European Standardization Organization (CEN) created EN 15251, a standard specifying the design values of the indoor thermal comfort. This standard defines four categories of buildings according to the occupants’ level of expectations, and the recommended design criteria depend on them. For example, category II refers to the normal level of thermal comfort expectations [1]:

| Category | Description |

| I |

High level of expectation, recommended for spaces occupied by very sensitive and fragile persons with special requirements, like the disabled, the sick, very young children, and the elderly.

|

| II |

Normal level of expectation should be used for new buildings and renovations.

|

| III |

An acceptable, moderate level of expectation may be used for existing buildings.

|

| IV |

Values outside the criteria for the above categories. This category should only be accepted for a limited part of the year.

|

The two metrics that are important for this code are PMV (Predicted Mean Vote) and PPD (Predicted Percentage of Dissatisfied). These metrics depend on several parameters related to indoor climate (air temperature, mean radiant temperature, air velocity, relative humidity) and people (physical activity, metabolic rate, clothing).

The PPD index is used to calculate the expected number of thermally dissatisfied occupants according to the PMV. For instance, the comfort zone for the category II (‘Normal level of thermal comfort expectation’) is defined by limiting the PMV between –0.5 and 0.5, with less than 10% of occupants being unsatisfied with the indoor environment. The following table contains the recommended criteria according to the building category, as specified in the EN 15251 standard [1]:

| Category |

Predicted Percentage of Dissatisfied

|

Predicted Mean Vote |

| I | <6% | -0.2<PMV<0.2 |

| II | <10% | -0.5<PMV<0.5 |

| III | <15% | -0.7<PMV<0.7 |

| IV | >15% | PMV<-0.7 or PMV>0.7 |

How CFD Can Help You Comply with EN 15251 and Other Industry Standards

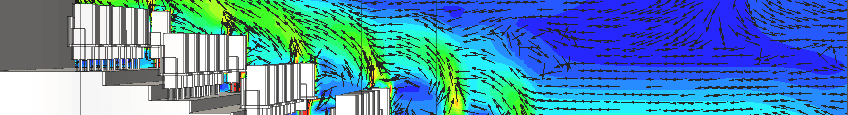

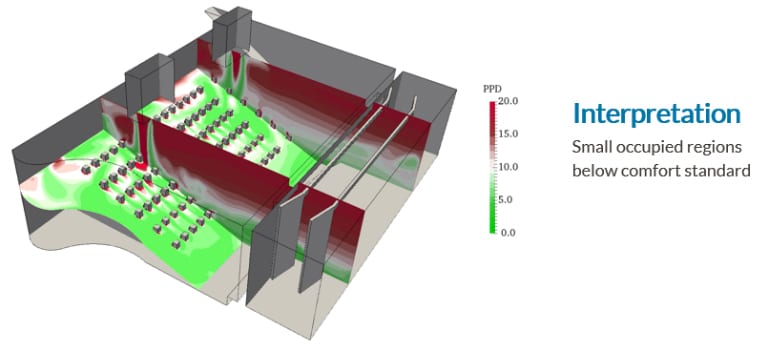

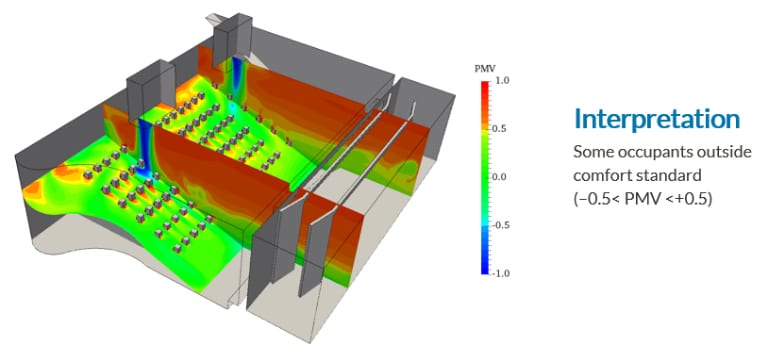

With the aid of CFD simulations, PMV and PPD can be computed as a field and visualized in post-processing, allowing the designer to identify potential design flaws and improvements necessary for compliance with EN 15251 and other thermal comfort standards. This type of information gives a powerful overview of the design’s performance as a whole, making it easy to compare multiple design configurations, accurately evaluating the impact of different modifications.

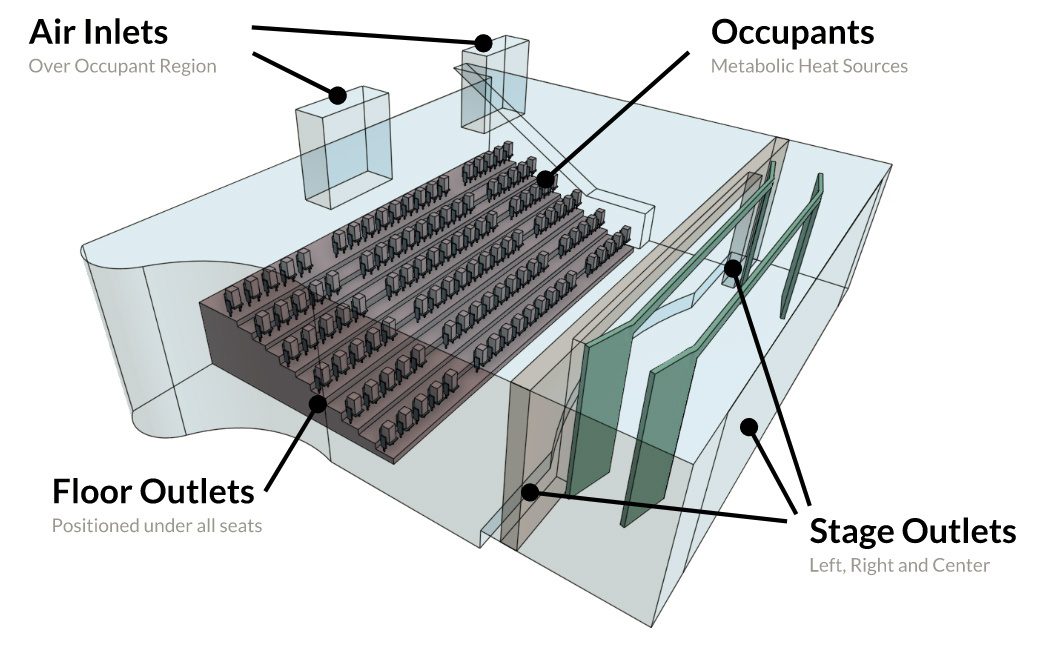

Consider the above example of an HVAC system for a large theatre room. In this design, the inlets are placed on top and no diffusers are used. If we aim for building category II (normal expectation), then we should keep the PPD under 10% and the PMV between -0.5 and 0.5. With that in mind, it becomes evident that this design has critical flaws. They are clearly revealed in the post-processing images of the CFD simulation results below, showing the PPD and PMV for the original design.

There are various design modifications which could potentially improve the thermal comfort of the occupants of this theatre room. Before the emergence of engineering simulation technology, HVAC design engineers had to base their design decisions on rules-of-thumb, experience, or intuition alone. But this approach does not guarantee reliable results and leads to additional costs caused by unforeseen design flaws.

To see how you can validate your HVAC system design with the help of CFD simulation, watch the recording of this free webinar, in which SimScale’s CEO, David Heiny, performs a live demonstration of the cloud-based platform:

Conclusion

The rapid population growth, the dense urban development, and the rising temperatures worldwide all contribute to the deteriorating air quality and thermal discomfort in public spaces. In order to reduce the energy consumption of a building while at the same time maintaining indoor thermal comfort, has resulted in the HVAC industry’s ongoing efforts to increase the efficiency and effectiveness of mechanical heating and cooling systems. As a result, building and thermal comfort standards are becoming increasingly restrictive, placing additional constraints on HVAC system designers.

The task of ensuring compliance with these standards has become a lot easier with the adoption of CFD simulation technology. Thanks to its ability to provide a detailed insight into the airflow pattern in the building, CFD has proven to be an invaluable tool in studies concerning ventilation system performance, thermal comfort, or indoor air quality. Until recently, the technology was only used by engineers and scientists with a strong theoretical background or those with access to the high-performance computing hardware that on-premises CAE software requires. However, with the emergence of flexible, cloud-based solutions like SimScale, which has an easy-to-use interface, it is quickly becoming an industry standard.

Whatever HVAC design solution you have, you are only a few hours or even minutes away from virtually testing it and predicting its performance. All you need is a standard PC or laptop and an Internet connection. In addition, if you want to read more about how CFD simulation helps engineers and architects improve building performance, download this free white paper.

References