An estimated 1,400 cars were reduced to burned-out shells on New Year’s Eve in King’s Dock, Liverpool. Despite the development of sophisticated smoke and gas detection devices, accidents like this happen on a regular basis, placing increasing importance on garage ventilation system design.

If a fire breaks out, the garage ventilation system needs to successfully extract the smoke and gas from the garage while ensuring a safe evacuation of any people in the building and, at the same time, reducing the temperature and maintaining sufficient visibility to make the firefighters’ job easier. Another equally important function is to maintain the fresh-air supply and extract toxic gases from the garage space to prevent the formation of “dead zones,” where harmful substances could accumulate.

This is the primary role of a garage ventilation system—affecting everyday user comfort, health, and safety.

Carbon Monoxide Removal: Why is It Important?

While the requirements for garage ventilation system design are generally based on different local standards, the system always needs to successfully perform two key tasks:

- Remove the pollutants emitted by cars

- In the event of a fire, it is crucial to control the hot fumes and gases produced by the fire, protect the escape routes, and maintain ease of access for the emergency teams.

In an enclosed parking garage with an inadequate or ill-maintained ventilation system, the fumes from the cars entering, exiting and driving through the facility could build up to toxic levels. Traditional parking garage ventilation systems combine supply and exhaust fans with ductwork to push fresh air in and pollutants, smoke and harmful emissions out. The major task for them is to extract harmful exhaust gases from an underground car park, such as Carbon monoxide (CO), Nitrogen oxides (NOx) and Sulphur oxides (SOx) which cause poor air quality.

CO concentration poses the biggest threat, causing harmful side-effects and even death, even in low quantities. It has no odor or color, but it can very quickly poison a person before they even sense anything is wrong. CO poisoning is the most common type of fatal air poisoning. If mechanical or natural ventilation is not sufficient in the enclosed environment, exhaust gas concentration is hazardous to humans and can even lead to death.

What International Standards Say about Parking Garage Ventilation System Design

| CO Level in Air | Standard and Regulation |

| 200 ppm | NIOSH – National Institute for Occupational Safety and Health Short-term exposure limit (15-minute maximum exposure level) |

| 50 ppm | OSHA – Occupational Safety and Health Administration The maximum allowable concentration for a worker’s continuous exposure in any eight-hour period |

| 50 ppm | UMC – Uniform Mechanical Code Recommends activation of the mechanical ventilation when CO is monitored in a parking structure |

| 35 ppm | EPA – Environmental Protection Agency Recommends 35 ppm or lower as an ambient air quality goal averaged over one hour |

| 35 ppm | NIOSH – National Institute for Occupational Safety and Health PEL-TWA : 35 ppm is the maximum allowable concentration for a worker to be exposed to in any eight-hour period |

| 25 ppm | ACGIH – American Conference of Governmental Industrial Hygienists TLV-TWA: 25 ppm is the maximum allowable concentration for a worker’s continuous exposure in any eight-hour period |

| 25 ppm | IMC – International Mechanical Code Recommends actuation of the mechanical ventilation when CO is monitored in a parking structure |

| 9 ppm | EPA – Environmental Protection Agency & ASHRAE – American Society of Heating, Refrigerating and Air-Conditioning Engineers Recommends 9 ppm or lower as an ambient air quality goal averaged over eight hours |

ASHRAE highlights the emission of carbon monoxide as one of the most serious concerns presented by car parking garages. For enclosed parking facilities, ANSI/ASHRAE Standard 62, “Ventilation for Acceptable Indoor Air Quality,” recommends 9 ppm or lower as an ambient air quality goal averaged over eight hours. Other engineering organizations set similar requirements, with 9-35 PPM maximum CO concentration over an eight-hour exposure period, and 100-200 PPM for short-term exposure.

Regardless of where the parking garage is located and the standards you follow, the consensus is that maintaining air quality while satisfying safety requirements is a key challenge for HVAC designers specializing in car park ventilation.

How Can CFD Help?

Finding the optimal location, number, and configuration of the exhaust fans required for garage ventilation, while ensuring that it meets the tenability requirements of CO exposure limit set by health and safety regulations, can be a challenging task. Computational fluid dynamics (CFD) can simultaneously predict airflow, heat transfer and contaminant transport inside the parking garage, guiding the engineer towards the right design decision.

To learn how to apply cloud-based CFD to test and optimize garage ventilation for the removal of carbon monoxide and other pollutants, watch the recording of this webinar:

Case Study: Reducing CO Concentration Levels in a Garage with Jet Fan Placement

Although natural ventilation may be sufficient for open and semi-open parking lots, channeled mechanical or jet fan ventilation systems should be used in underground and closed parking garages in order to prevent excessive CO concentration levels. The jet fan ventilation system is one of the most widely used ventilation systems for carbon monoxide extraction in underground car parks. The aim of this study is to undertake CFD modeling of a car park to simulate how the correct placement of a jet fan can help to reduce CO concentrations without the need for a complex duct system.

For this case study, we will use a project from the SimScale Simulations Library: Pollutant Extraction from a Parking Garage. The aim of this project is to evaluate ventilation performance in an underground car parking garage and to verify that the jet fan ventilation system causes a sufficient reduction in CO concentration levels.

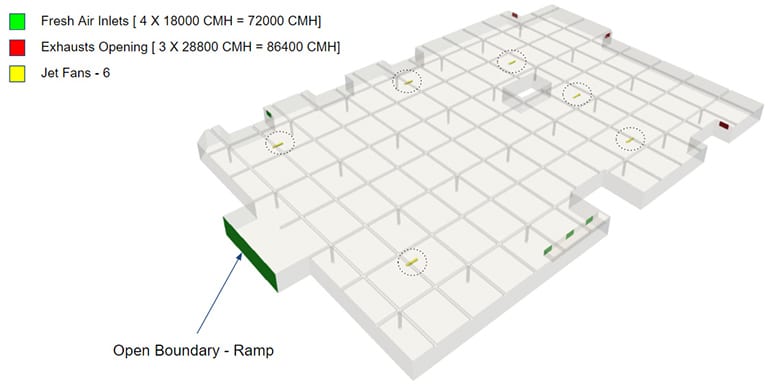

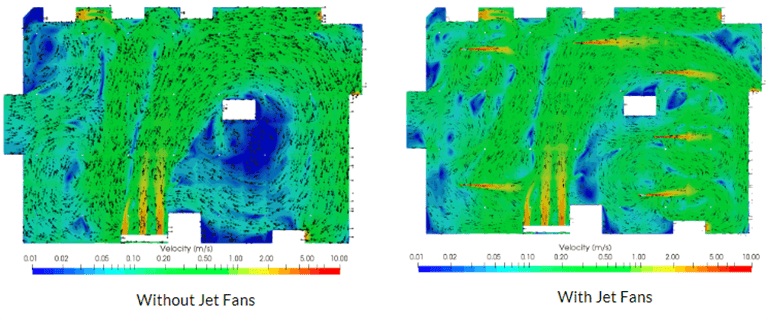

Two garage ventilation system configurations are simulated:

- Without jet fans (only supply and exhaust fans opening)

- With jet fans

CFD simulations are performed to examine velocity and CO concentration distribution for the two scenarios using the simulation parameters below.

Simulation Parameters

The computational domain consists of a parking garage measuring 3.5 m in height and having a total volume of 23642 m^2.

Boundary Conditions:

- Fresh Air Inlets [ 4 X 18000 CMH = 72000 CMH]

- Exhausts Opening [ 3 X 28800 CMH = 86400 CMH]

- Jet Fans

- Open Boundary (ramp for entry/exit)

CO Source Term Calculation:

| Volume of underground parking garage (m^3) | 23642 |

| Total number of vehicles parked | 200 |

| % of moving cars (entering/exiting the garage in peak hours – worst case scenario) | 40 |

| Total number of moving cars | 80 |

| CO emission rate per vehicle (mg/s) | 8.1944 |

| Total volumetric CO source (Kg/m^3-s) | 2.77E-08 |

CFD Simulation Results

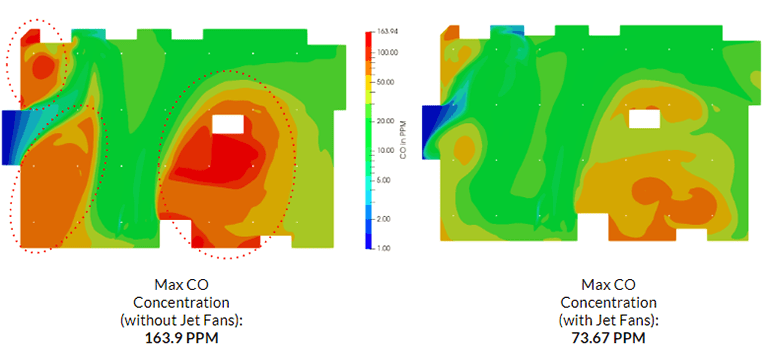

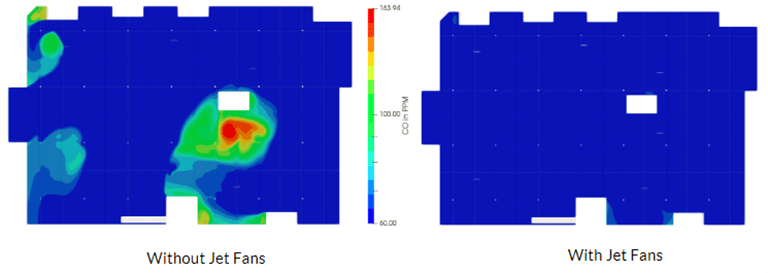

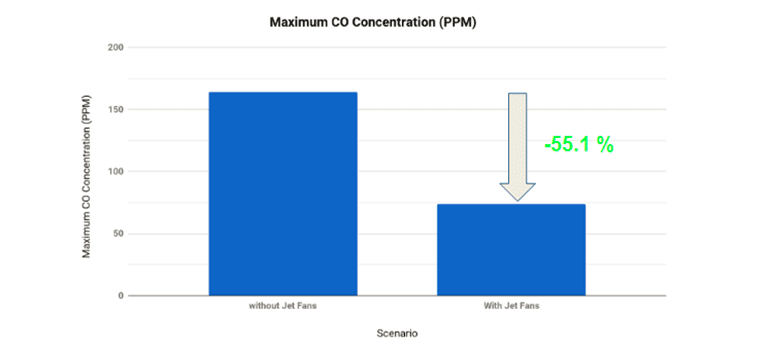

The simulation results visualize the CO concentration patterns for both garage ventilation system designs, clearly revealing several large “dead zones” in the first configuration without jet fans. The post-processing images below further highlight the regions with CO concentration over 60 PPM in the first design, which have been eliminated with the help of jet fan placement.

To put these results into numbers, incorporating jet fans into the garage ventilation system can lower the maximum CO concentration by 55,1%! That is in addition to improving air velocity and the overall air quality throughout the garage space.

Conclusions

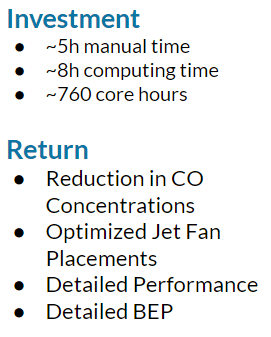

The above case was just a simple example of how cloud-based CFD simulation can help HVAC design engineers easily test any design change without leaving the web browser. The simulation took only five hours of manual time and eight hours of computing time, allowing us to virtually investigate the performance of a garage ventilation system and ensure the adequate movement of air.

Until recently, only engineers with vast expertise in numerical analysis and a large budget could fully benefit from CFD simulation tools. With the emergence of flexible cloud-based solutions, however, it has become an industry standard. To see the SimScale platform in action and learn more about setting up a typical pollutant removal simulation with cloud-based CFD software, watch the webinar recording below:

References

- http://inteccontrols.com/whitepapers/CO_Parking_Garage_Design_Guidelines.pdf

- http://www.honeywellanalytics.com/~/media/honeywell-analytics/documents/english/apn069_parkinggarage_web_1-8-15.pdf

- http://www.mobilecalibrationservices.com/Ventilation_for_enclosed_parking_garages.pdf