Better future for children in Ethiopia through water, sanitation, and hygiene projects

Water is an essential source of life, but when contaminated, it is also the leading cause of death worldwide. Each year, around 361,000 children aged under five, living in the low- and middle-income countries, die as a result of waterborne diseases. These diseases develop and spread due to inadequate sanitation and hygiene.

Water and sanitation scarcity forces children growing up in the poorest regions of the world to fight each day for survival, leaving little time or energy to attend a school.

Neven Subotic Stiftung decided to tackle that problem. The nonprofit organization, which was created by Neven Subotic in November 2012, is solely focused on funding the so-called “WASH projects” (Water, Sanitation, and Hygiene), which they believe can create a better future for the children living in places like the rural areas of Ethiopia. “Our dream is to live in a world in which health, education and a positive future are available to every child. Through the production of clean water wells, safe latrines for girls and boys, as well as awareness regarding the hygienic aspects of these facilities, the children are able to miss fewer days at school and enjoy humane conditions on their quest to a better future,” says Neven Subotic.

In the past five years, through the WASH projects, Neven Subotic Stiftung has provided nearly 50,000 people in Ethiopia with life’s most important and basic needs.

Partnering with SimScale

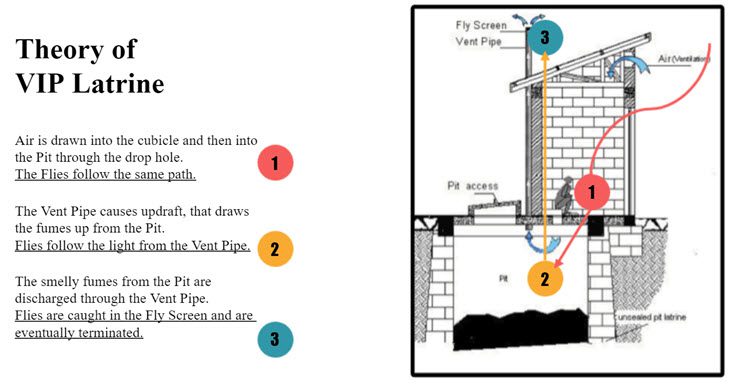

Their most recent project focuses on designing and building safer sanitary facilities, such as the ventilation improved latrines, which are in line with the UN standards of improved sanitation. These latrines have a system in place to ensure that excreta are treated or disposed of safely, with adequate ventilation, and a mechanism that captures flies. Implementing these facilities prevents the spread of diseases like cholera, diarrhea, dysentery, hepatitis A, typhoid, and polio. A WHO study in 2012 calculated that for every US $1.00 invested in sanitation, there was a return of US $ 5.50 in lower health costs, more productivity, and fewer premature deaths. In addition to that, the project also helps to promote school attendance among girls, which is proven to be correlated with the provision of separate sanitary facilities.

For their sanitation project, Neven Subotic Stiftung decided to go with an optimized version of the design of a VIP latrine (Ventilated Improved Pit Latrine) which has been used as a standard design by many other NGOs since the 60s. Based on online research, they have determined that updating this design could potentially improve its effectiveness. Unfortunately, with a very limited selection of articles providing accurate evidence of the improvement, it was hard to prove its effectiveness without actually building dozens of latrines and running the tests manually. This obviously wasn’t a feasible solution given the limited financial resources.

Neven decided to incorporate computer-aided engineering (CAE) into the project, knowing that it would be able to provide precise and clear results that his organization needed in order to move forward with their sanitation project. “There are millions of people using this standard design of the latrine but barely any testing has been done, and to our knowledge, none with the precision of a CAE solution. Therefore, the benefit of using CAE would not only be changing the design of our own latrine but also providing best-practices to other organizations who are building such sanitation systems,” he said when asked about the benefits he saw in partnering with SimScale.

When Neven reached out to SimScale to get our support with testing his design, our immediate response was “Let’s do it!”. Our entire team was very excited about the project and the potential positive impact it can have. We met with Neven and agreed to put two hypotheses to the test:

- Updating the design of the latrine would improve its effectiveness

- Increasing the vent pipe diameter of the latrine pipe from 100mm to 150mm would improve the ventilation

Getting to the 5.75x Improvement in Ventilation

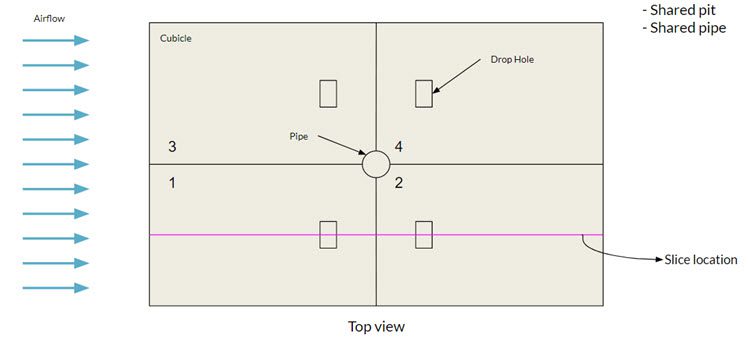

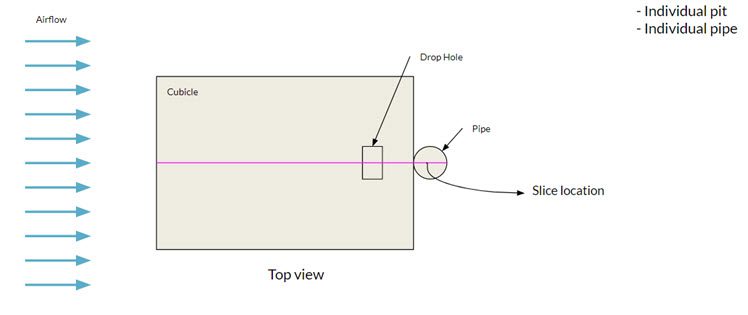

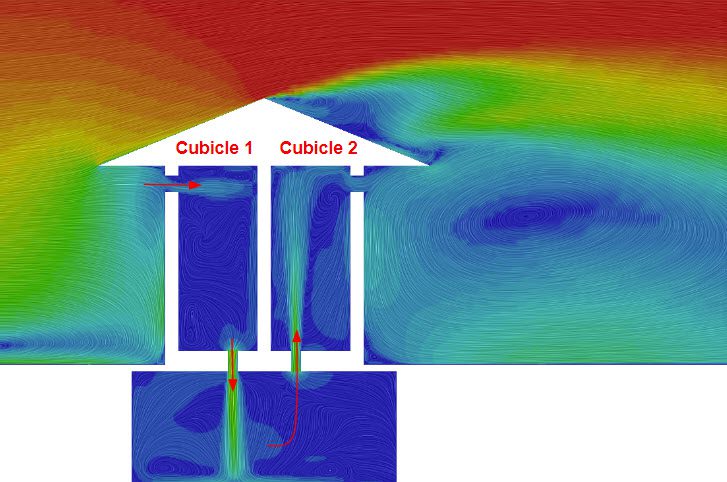

The project was assigned to Diego, one of our Application Engineers at SimScale. Diego first created two geometries: one according to the dimensions of the old design and the second one following the design changes suggested by Neven Subotic Stiftung. The main difference between the two designs was that the old design consisted of four cubicles, with two cubicles placed back to back in one building, which were connected through a 100mm pipe and a pit. In contrast, the new design had both an individual 100mm pipe and an individual pit.

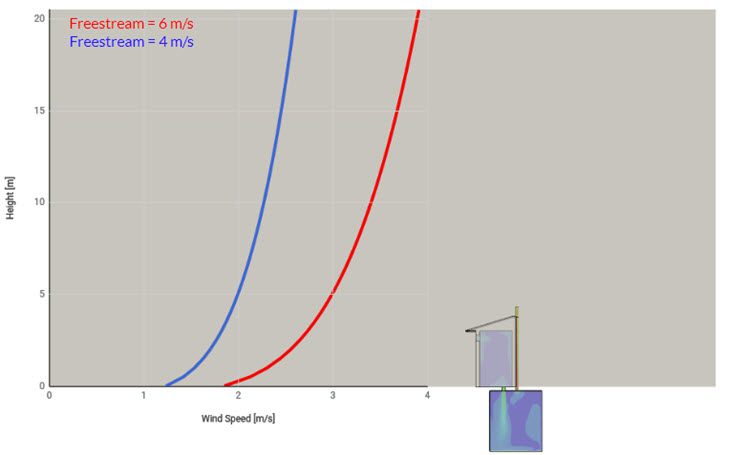

The next step was defining the average and maximum wind speed in the specific area of Ethiopia where the latrines were planned to be built. Neven provided us with the GPS coordinates of the area. Using the data reported by the Windfinder, Diego estimated that we should focus on the freestream wind speed of 4m/s (as an average for the region throughout the year) and 6m/s (as a maximum wind speed reported for the region) when running the simulation.

The next step was to set up the simulations and compare the results of both designs. After running the CFD simulations, we were able to clearly see that the new design was a game-changer. It removed the main issue of the standard design, where an individual cubicle was affected by the neighboring one due to the shared pit and pipe. In the old design, 87% of the air pushed through the pit (containing the odors and the flies) was ending up in the neighboring cubicle, requiring between 45 minutes (with the wind speed of 6m/s) and 75 minutes (with the wind speed of 4m/s) for the air inside the latrines to be circulated. The new design, which had a pit and a 100mm pipe per latrine, allowed the air to move through the cubicle, to the pit, and out through the exhaust pipe without going in the opposite direction. This dropped the air circulation time to between 28 minutes (with the wind speed of 4m/s) and 18 minutes (with the wind speed of 6m/s). This way, we were able to prove with data that the first hypothesis was correct. Updating the design of the latrine would improve hygiene and comfort, and would also greatly reduce the risk of diseases transmitted by the flies.

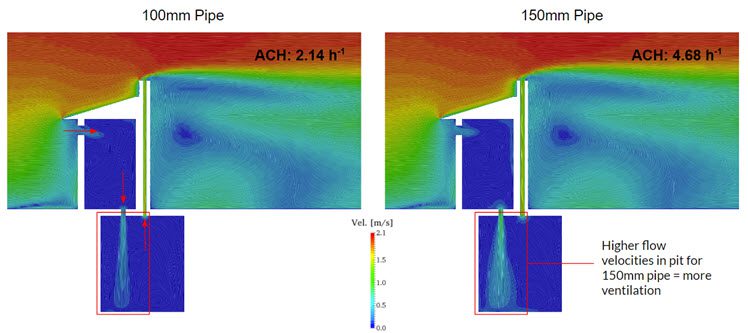

We were now ready to test the second hypothesis: Increasing the vent pipe diameter of the latrine pipe from 100mm to 150mm would improve the ventilation.

For this, Diego ran the following four simulations:

- For a new latrine design with a pipe diameter of 100mm for a wind speed of 4m/s

- For a new latrine design with a pipe diameter of 150mm for a wind speed of 4m/s

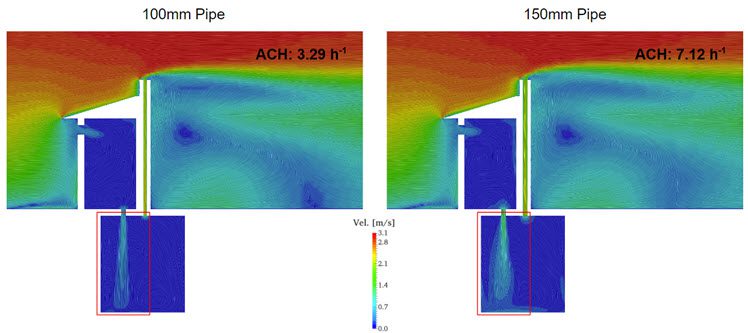

- For a new latrine design with a pipe diameter of 100mm for a wind speed of 6m/s

- For a new latrine design with a pipe diameter of 150mm for a wind speed of 6m/s

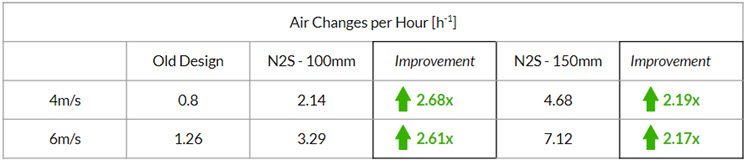

For both wind speeds of 4m/s and 6m/s, the increase of the pipe diameter from 100mm to 150mm resulted in an average 2.18x more flow through the latrine. The analysis showed us that the new design with an increased pipe diameter of 150mm would bring the air quality of these latrines closer than ever to the industry standards of commercial bathrooms. It would only take between 8 and 12 minutes to circulate the air in the latrine with the fresh air from outside.

A comparison of the improvement in the flow showed that the new latrine design combined with the 150mm pipe would improve the ACH values by a factor of 5.75x when compared to the standard design. More flow would mean better ventilation, a reduction in odors inside the latrine, and more flies being pushed through the drop hole and up the pipe into the fly screen.

This free infographic illustrates how architects and engineers can use CFD to virtually test and optimize building designs and HVAC systems. Download it for free.

From Product Design Validation to Building New Latrines

For Neven Subotic Stiftung, the results surpassed their initial expectations from this collaboration. “The SimScale expertise and support became key to the success of this project since knowledge and understanding of CAE and CFD was something we do not have. Beyond the professionality of achieving the goals set forth at the beginning, SimScale’s team really did help me understand what exactly was going on and which factors played key roles,” said Neven. “The decision has been made to birth the new design from now on, therefore the old design is history. We learned our lessons based on the very clear information provided by SimScale and are passing this lessons on to our partners,” he added.

The new design approach that was tested and confirmed with the help of SimScale will be accepted and put into production by the beginning of 2018. 14 latrines have been planned to be completed by the mid-2018. Neven Subotic is also planning to present the findings to the local ministries and to the organizations partnering with his nonprofit in order to further encourage the optimization of the standard design. “Doubling the ventilation at almost no cost is a pretty good deal. We will continue to help other regional and national organizations to update their designs and take into consideration what was developed with the help of SimScale. Afterwards, we hope to move this also to the international level.” he concluded.

If you’d like to support Neven Subotic Stiftung’s 100% WASH projects in Ethiopia, you can donate here. 100% of your donation will be invested in the projects.

Download this case study for free to learn how the SimScale CFD platform was used to investigate a ducting system and optimize its performance.